舵机功能试验翻译英文,舵机功能试验翻译英文

舵机功能试验翻译英文

Understanding the Functionality of Servo Motors Through Parameter Analysis

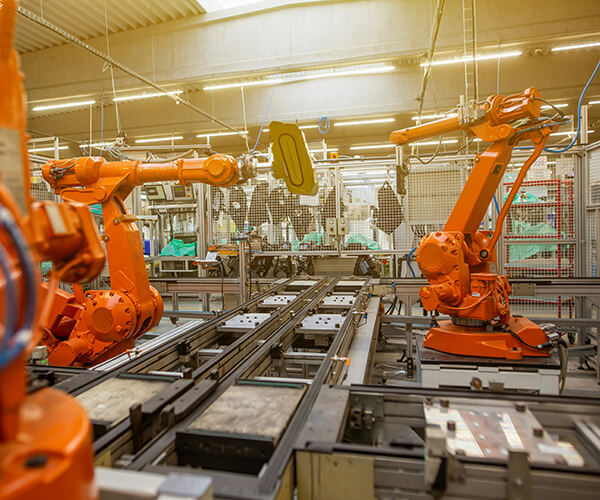

Servo motors, a cornerstone in industrial automation, have become indispensable in applications ranging from robotics to automotive systems. Their precision and reliability make them a favorite in industries where control and accuracy are paramount. This article delves into the functionality of servo motors, highlighting crucial parameters that define their performance, and answers common questions that may arise during selection and integration.

At the heart of any servo motor's operation lies its ability to convert electrical energy into precise mechanical motion. This process is governed by several key parameters, each playing a vital role in determining the motor's suitability for specific applications. Below, key parameters are examined along with their implications:

Key Parameters of Servo Motors

Torque: Measured in Newton-meters (Nm), torque represents the rotational force the motor can exert. It is crucial for applications requiring heavy loads or those involving frequent starts and stops.

Speed: Expressed in revolutions per minute (RPM), speed determines how fast the motor can rotate. High-speed applications, such as packaging machines, benefit from motors with higher RPM ratings.

Control Signal: Typically ranging between 1-2mA, this parameter ensures precise control of the motor's position. A stable control signal is essential for accurate motion control.

Positioning Accuracy: This is measured in encoder counts or degrees and dictates how precisely the motor can reach its target position. Applications requiring high precision, such as CNC machines, demand motors with high positioning accuracy.

Environmental Resistance: Parameters like IP ratings indicate the motor's protection against dust and water, crucial for industrial environments.

Decoding the Parameters

When selecting a servo motor, understanding these parameters is key. For instance, a motor with high torque is better suited for handling heavy loads, while one with high speed is ideal for applications requiring rapid movement. The control signal's stability ensures smooth and precise operation, while positioning accuracy guarantees that the motor reaches the intended position every time.

Frequently Asked Questions

Q: How does the control signal affect the motor's performance?

The control signal governs the motor's response to commands. A stable and consistent signal ensures smooth operation and precise positioning.

Q: What determines the positioning accuracy of a servo motor?

Positioning accuracy is primarily determined by the encoder's resolution and the system's feedback mechanism. Higher encoder counts result in more precise positioning.

Q: Can servo motors operate in harsh environments?

Yes, servo motors can be designed with various protection ratings (IP ratings) to operate in dusty or wet environments. Selecting the right rating is crucial for optimal performance.

Q: How is torque related to speed?

Generally, as speed increases, torque decreases, and vice versa. The relationship between torque and speed depends on the specific motor design and application requirements.

A Closer Look at Parameters

To further illustrate the importance of these parameters, let's compare different servo motor models based on key specifications:

| Parameter | Model A | Model B | Model C |

|---|---|---|---|

| Torque (Nm) | 50 | 75 | 100 |

| Speed (RPM) | 3000 | 2500 | 2000 |

| Control Signal | 1.5mA | 2mA | 2mA |

| Accuracy | 10 encoder | 20 encoder | 30 encoder |

| Environment | IP54 | IP66 | IP69 |

This table highlights how different models cater to various application needs. For instance, Model C offers higher torque and better environmental resistance, making it ideal for industrial settings, while Model A, with its higher speed, is suited for applications requiring rapid movement.

Conclusion

Servo motors are a sophisticated blend of engineering excellence and precision mechanics. By understanding and carefully selecting the right parameters, one can unlock the full potential of these motors in diverse applications. At [Your Company Name], we specialize in providing servo motors that meet the exact needs of our clients, ensuring reliability and performance.

伟创动力(Kpower)成立于2005年,定位于专业的一体化驱控动力单元服务商。我们的使命是通过模块化驱动技术创新,整合高性能电机、精密减速器、多协议控制系统等核心部件,为客户提供高效、定制化的智能驱动系统解决方案,为每个产品注入动态的生命力。公司位于东莞市横沥镇,现有员工300余人,拥有47,000m²的生产制造场地,每月生产传动模组/电机超过650,000。我们已在全球范围内为500+客户提供驱动系统解决方案,产品覆盖智能家居、智能座舱、机器人、智慧农业、无人机、医疗、工业自动化等多个领域。